Fine ceramics, also known as advanced ceramics or technical ceramics, are a group of inorganic, non-metallic materials that exhibit remarkable properties, including high strength, hardness, wear resistance, and thermal stability. They are typically manufactured through precise control of chemical composition, powder processing, and high-temperature sintering.

1.Superior Mechanical Properties: Fine ceramics possess exceptional mechanical properties, such as high compressive strength, hardness, and stiffness. They can withstand extreme conditions, including high temperatures, corrosive environments, and abrasive wear, making them ideal for demanding applications where conventional materials fall short.

2.Excellent Thermal Stability: Fine ceramics exhibit excellent thermal stability, allowing them to retain their structural integrity and mechanical properties even at elevated temperatures. This makes them suitable for applications requiring heat resistance, thermal insulation, and thermal shock resistance.

3.Chemical Resistance: Fine ceramics are highly resistant to chemical attack, making them ideal for applications involving exposure to corrosive substances or harsh chemical environments. They do not easily react with acids, alkalis, or solvents, ensuring long-term performance and reliability.

4.Electrical Insulation: Fine ceramics have excellent electrical insulation properties, which make them valuable in applications where electrical conductivity needs to be minimized or controlled. They are widely used in electronic components, insulators, and substrates for electronic devices.

5.Biocompatibility: Certain types of fine ceramics exhibit excellent biocompatibility, meaning they are well-tolerated by the human body. This makes them suitable for medical and dental applications, including implants, prosthetics, and surgical instruments.

Aerospace and Defense: Fine ceramics find extensive use in the aerospace and defense industries, where their exceptional properties contribute to the production of turbine blades, heat shields, rocket nozzles, and armor systems. Their high strength, thermal stability, and lightweight nature are crucial for these demanding applications.

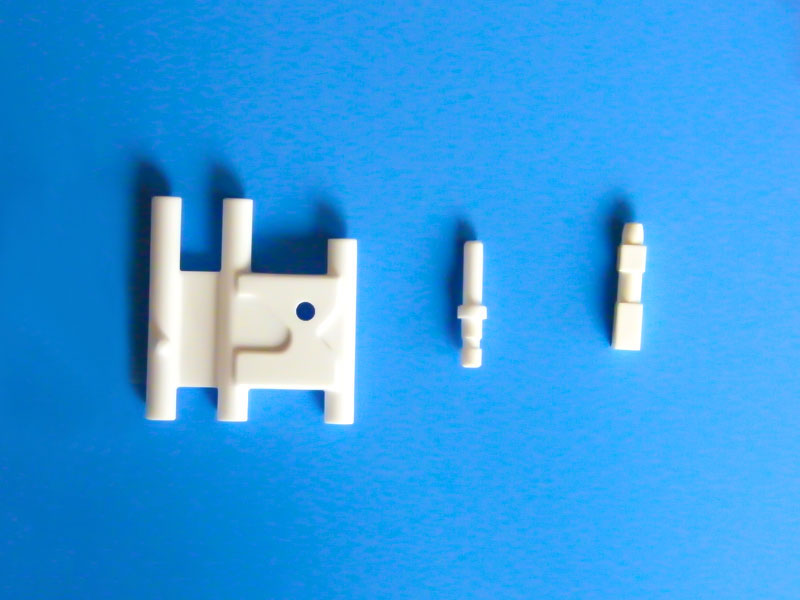

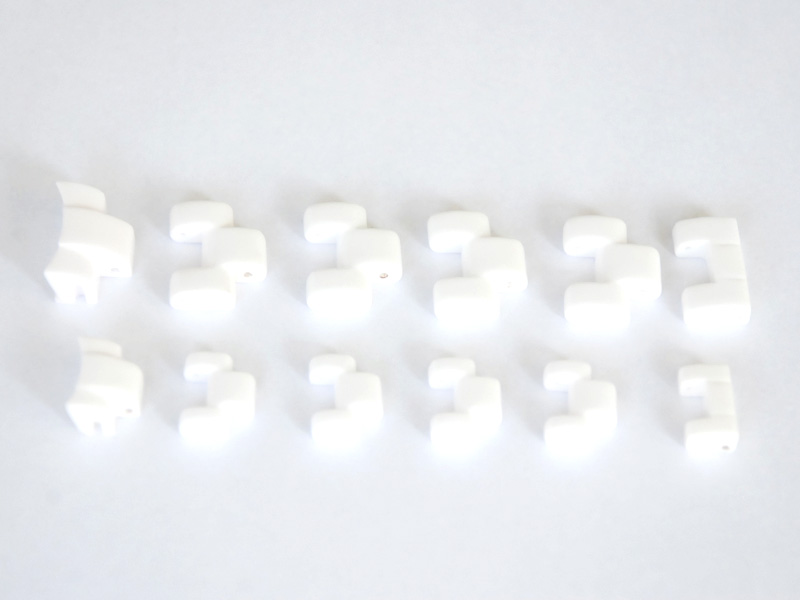

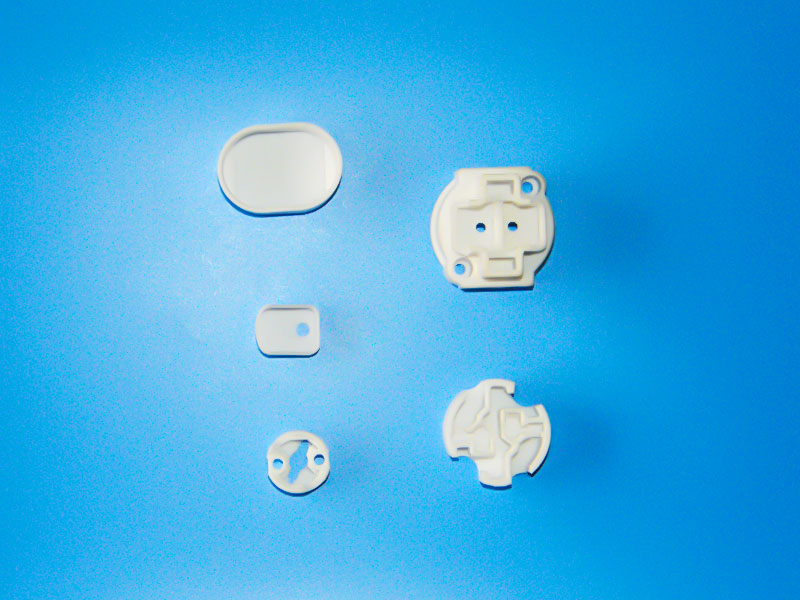

Electronics and Semiconductors: Fine ceramics play a critical role in the electronics and semiconductor industries. They are used for manufacturing substrates, capacitors, resistors, sensors, and insulating components. The combination of electrical insulation, thermal stability, and high dielectric strength make them ideal for these applications.

Automotive and Transportation: Fine ceramics are employed in automotive and transportation applications, such as engine components, exhaust systems, braking systems, and bearings. Their high temperature resistance, wear resistance, and low friction properties contribute to improved performance, efficiency, and durability.

Medical and Dental: Fine ceramics have made significant contributions to medical and dental fields. They are used for dental implants, joint replacements, surgical tools, and diagnostic equipment. The biocompatibility, strength, and resistance to wear and corrosion make them valuable in these applications.

Origin:Ningbo,China

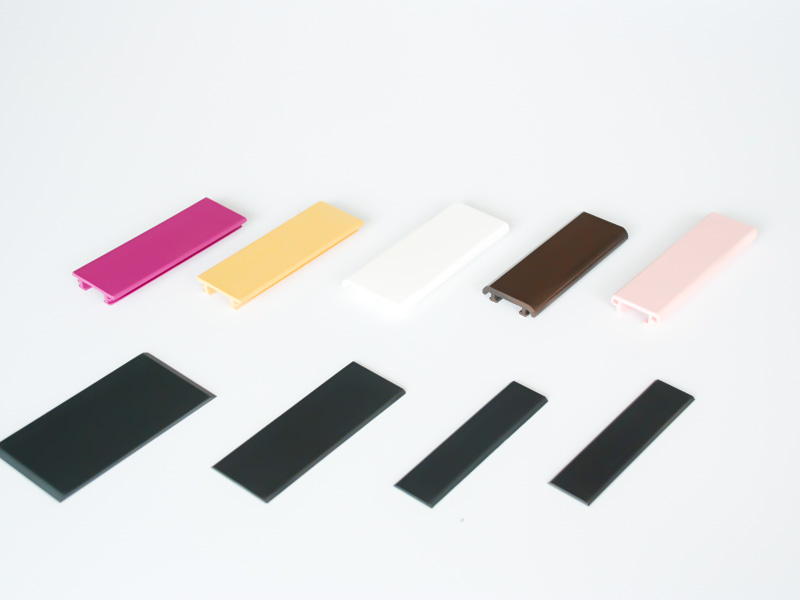

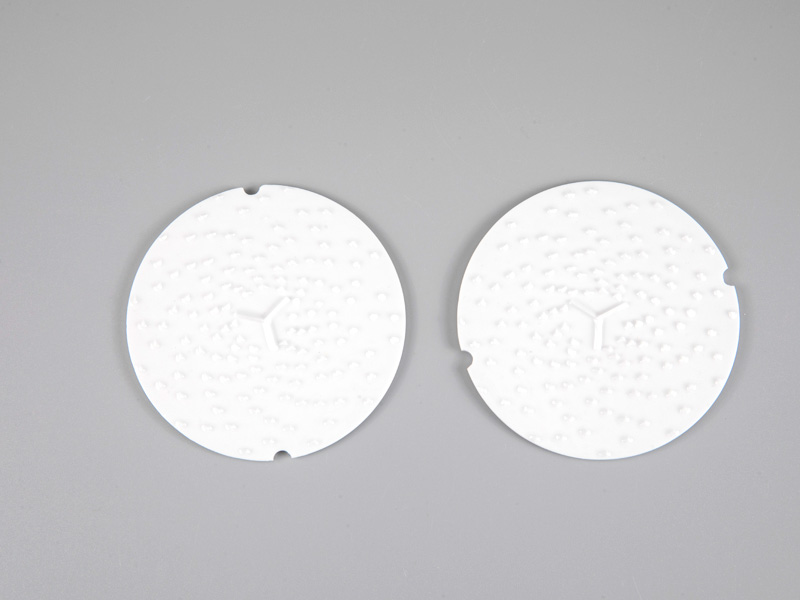

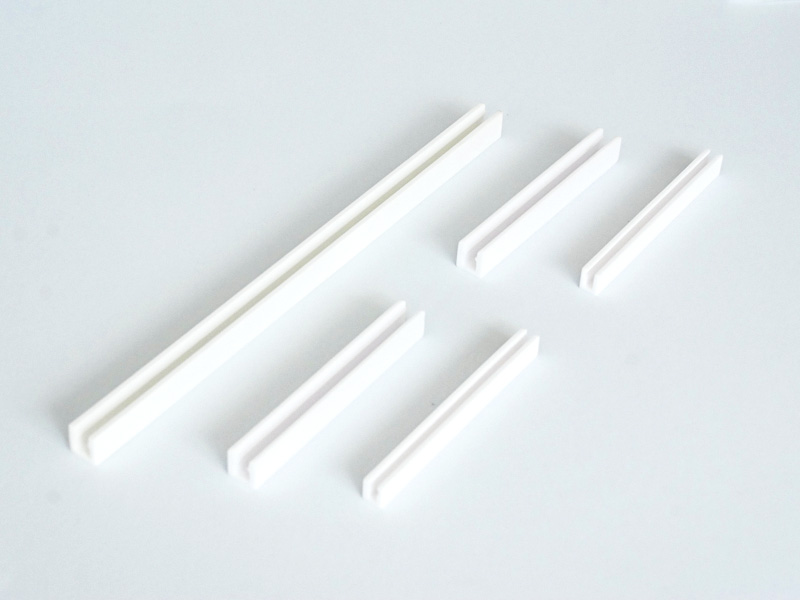

Application:Industrial ceramics, machinery, electronics, chemicals, petroleum, etc.

Model:95 Alumina

Processing Service:Bending, welding, cutting, punching, uncoiling, forming, grinding, washing, drilling, etc.

EN

EN

Chinese

Chinese